Tools

GUIDE Methodology

GATHER: The Gather phase provides a systematic method for identifying stakeholders and gathering supporting material. By gathering consensus from applicable and relevant stakeholders at the beginning of the process, accountability is set early through collaborative and supported conversation.

UNDERSTAND: The Understand phase assesses and analyzes the information to provide a cohesive picture of requirements building a broader understanding of desired outcomes.

INTENT: The Intent phase incorporates the understanding of desired outcomes into documents that meet the intent

DOCUMENT: The Document phase builds the individual documents and includes both review and validate steps. The GUIDE methodology uses a one review cycle process to move from a draft document to a working final copy. This allows for mid-stream adjustments to the standards and a shake-down period for the review team of organizations staff and stakeholders.

EXECUTE: The Execute phase is the most programmatic and implements the procedures through a sustained training and revision approach. It involves training documents management of the creating, reviewing, and validation of documents.

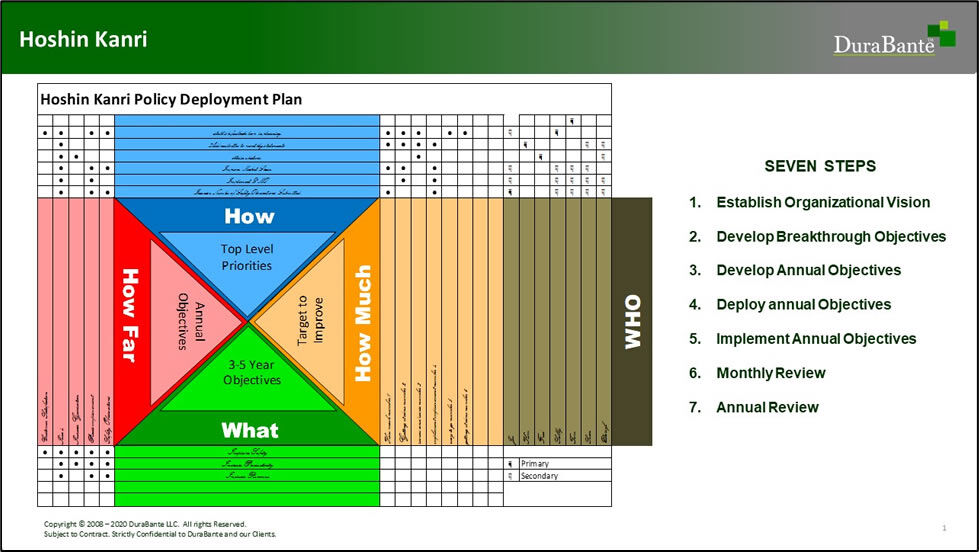

HOSHIN KANRI

Hoshin Kanri is a seven step planning tool for ensuring that an organization’s strategic goals are supported at every level within the company. The unified strategy drives progress and eliminates waste that comes from inconsistent direction and poor communication.

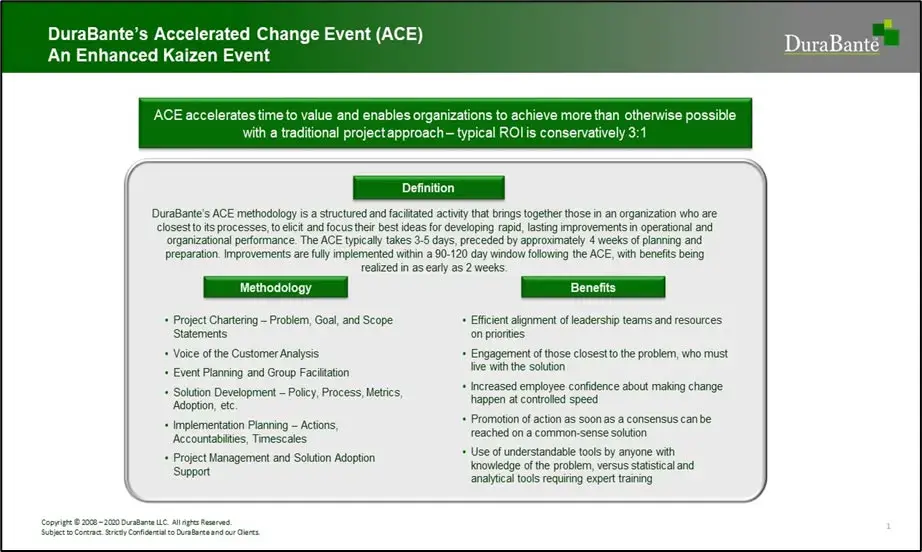

KAIZEN

Kaizen is often considered synonymous with Continuous Improvement. It is based upon the philosophical belief that everything can be improved. These efforts are usually seen as small, often imperceptible changes over time that add up to significant changes over the longer term without having to go through potentially disruptive events. Utilizing kaizen principles throughout an organization provides a smooth method to scale a business as it grows.

- Enhanced Kaizen Events/Accelerated Change Events [ACE]

LEAN SIX SIGMA

Lean Six Sigma is a proven process improvement approach that focuses on reducing or eliminating activities that do not add value to a process.

Lean Six Sigma is a proven process improvement approach that focuses on reducing or eliminating activities that do not add value to a process.

Continuous Improvement through Lean:

Lean Thinking can be summarized in five principles*:

Principle 1 - Specify and Focus on value

Principle 2 - Identify the Value Stream

Principle 3 - Allow value to flow without interruptions

Principle 4 - Let the customer pull value

Principle 5 - Continuously pursue perfection

The combination of Lean and Six Sigma is to both Reduce Variation and Correct Defects/Defectives to both processes and products. In the context of a process-driven enterprise, the first three items concentrate on efficiency (Variation). This means being able to identify exactly the process output or deliverable that the customer is willing to pay for, determining the minimum set of tasks/activities that are needed to deliver that value and reduce cost, eliminating barriers, and allowing things to flow and work. The fourth and fifth principles focus on Effectiveness (Defects/Defectives) and are more subtle. These create processes that can be repeatable and reproduceable for the deliverables while at the same time being aligned with value to the customer. This alignment happens through a feedback loop of direct inputs from the customer. The fifth principle simply acknowledges that firms must continuously attack waste in their processes, because if we are not vigilant, the process will return to its original state. Workers and the process will degrade processes with new forms of waste and inefficiency.

Reference*:

These principles were first proposed in a 1996 book by Womack, Jones, and Roos entitled "Lean Thinking."

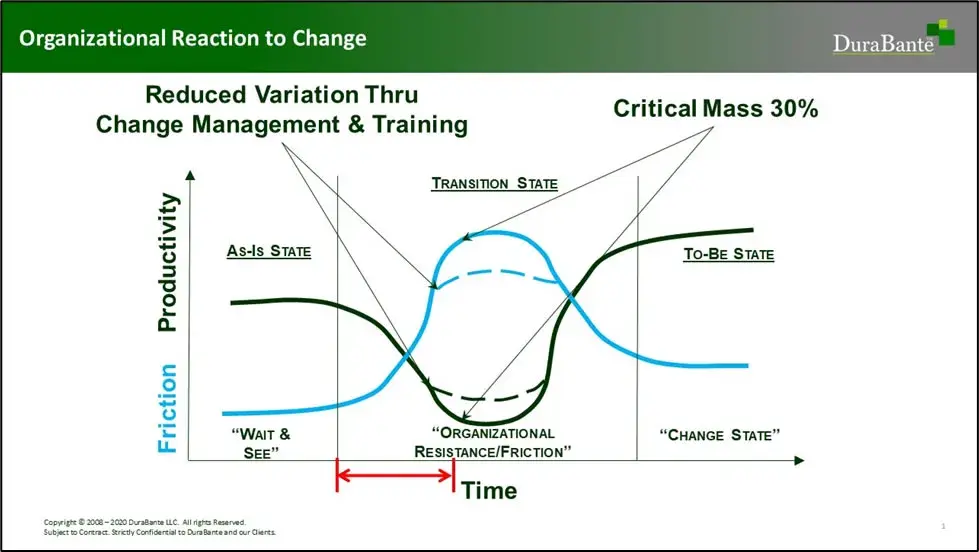

HOW ORGANIZATIONS REACT TO CHANGE

For more about the principles of this model, check out this informative video from our CEO and President, Scott Thompson.

SIX SIGMA

The robust roadmap of problem solving used in Six Sigma is called DMAIC. The acronym is Define (Tell me the problem.), Measure (How bad is it?), Analyze (What is the root cause?), Improve (Go fix it.), and Control (Make sure it does not happen again.). This is a quality roadmap, and many of the tools have been used individually by Quality Professionals from Blue Prints, Gage Studies, Design of Experiments, and Control Charts. However, it was the linking of all of these tools and more into a process that led to a revolution in problem solving focused on the customer, business, and costs.

The robust roadmap of problem solving used in Six Sigma is called DMAIC. The acronym is Define (Tell me the problem.), Measure (How bad is it?), Analyze (What is the root cause?), Improve (Go fix it.), and Control (Make sure it does not happen again.). This is a quality roadmap, and many of the tools have been used individually by Quality Professionals from Blue Prints, Gage Studies, Design of Experiments, and Control Charts. However, it was the linking of all of these tools and more into a process that led to a revolution in problem solving focused on the customer, business, and costs.

Six Sigma has been communicated as a process for manufacturing products or services. However, the true history is linked for both services directly tied to consumers and to processes that improve customer experiences. Six Sigma is known for the use of statistics to help identify opportunities, tp test hypothesis for both detection and improvement, and finally to use control charts and statistical proof that the problem has been solved.

The basis of hypothesis testing using the Student-T test was introduced in 1908, when W.S. Gosset developed statistical tests to help analyze quality data obtained at Guinness Brewery. Workin within queueing of phone calls and service levels, A.K. Erlang studied telephone traffic and developed a quadratic formula, Erlang-C, that is still used today in Call Centers. The combination of Probability ahd Reliability forecasting and modeling was a critical milestone for inferential statistics.

To control processes, the process must maintain stability, and trends are tracked for both positive and negative effects. Walter Shewhart worked with Western Electric (a forerunner of AT&T) in the 1930s to develop the concepts of quality control. Shewhart is also known as the originator of the Plan-Do-Check-Act cycle, which is sometimes ascribed to Dr. Edwards Deming, Shewhart’s understudy. Dr. Deming has modified this to become Plan-Do-Study-Act (PDSA). Both are tenents that lead to the Measure-Analyze-Improve-Control from Motorola and then finally the Define-Measure-Analyze-Improve-Control from ABB (Dr. Mikel Harry), General Electric, and Allied Signal.

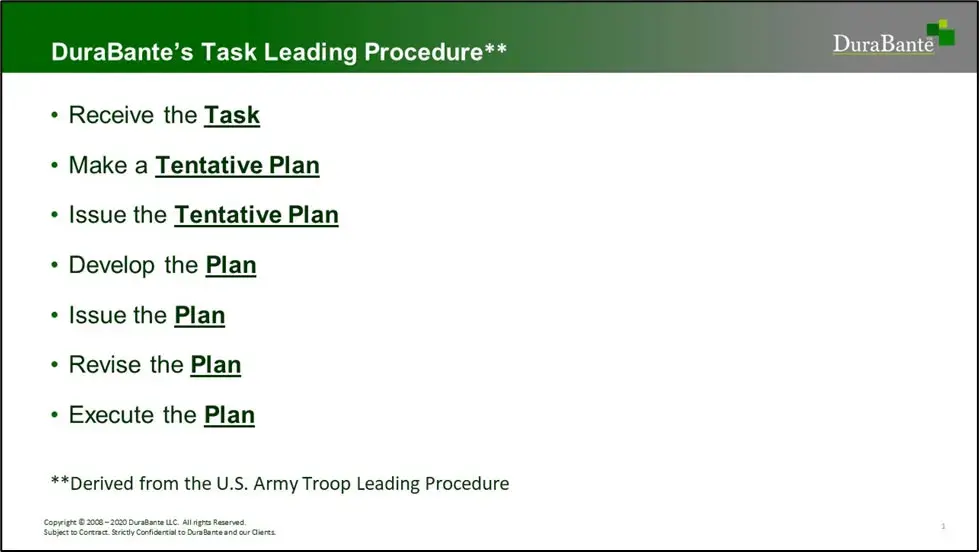

TASK LEADING PROCEDURE